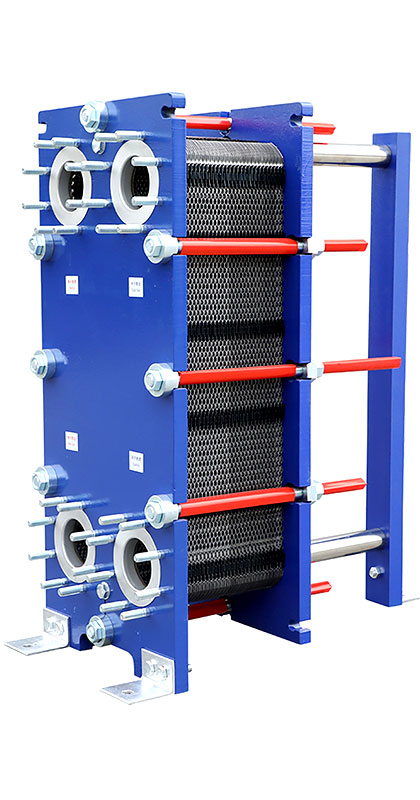

Shanghai Jiangxing Chemical Equipment Co., Ltd. is located on Economic, financial and trade center city——Shanghai, China and founded in March 12,2010. Shanghai Jiangxing is an enterprise specialized in manufacturing series of plate heat exchanger. The company has the abundant technical force, 10000 tons of hydraulic press and other important equipment, specializing in removable plate heat exchanger, fully weld plate heat exchanger, heat exchanger unit, plate and gasket, brazed plate heat exchanger design, development, manufacturing, sales and service.

|

10000+ Area Covered |

60+ Employees |

9Million+ Value of annual Production |

Even a plate heat exchanger can have problems during the course of a year and require maintenance, especially its seals, to see if it has loosened. Here is the content list: Secondary adjusutment precautions Gasket bonding Repair and replacement Secondary adjustment precautions A plate heat exchanger is an important component of heat exchange technology in process industry equipment. The elastic gasket that seals between the individual plate heat sinks is a wearable part and one that is prone to deterioration under natural conditions. If these seals harden thermally and lose their original elasticity, the heat exchanger can not work properly. The softening…

With increasing use, the heat exchanger's heat transfer efficiency will inevitably be affected, thus affecting normal operation. There are many reasons for the low heat transfer efficiency of plate heat exchangers. Because we all know that the plate heat exchanger heat transfer efficiency is very high, and this is one of the reasons why people often choose it. Today we will discuss this issue. Here is the content list: Wrong choice of material The abnormal flow rate or blockage Unreasonable structure Wrong choice of material The choice of the wrong material will affect the heat exchanger heat transfer area, many…

Plate heat exchangers were first put into commercial production in the 1930s and are now being used more and more widely in water supply, heating, and air conditioning projects in industrial and civil buildings. The correct selection of plate heat exchangers can ensure the smooth implementation and use of the project. Here we introduce how to select the heat exchanger. Here is the content list: Material of construction Blocking tendency Maintence Pressure Drop Material of construction Because compared with the tube or other heat exchanger's heat surface, plate heat exchanger heat exchange surface is quite a book, only 0.5 mm, corrosion…

Plate heat exchangers have been widely used in central heating, food, machinery, metallurgy, the petrochemical industry, and ships, and have become the leading heat exchange equipment in urban central heating projects. In order to ensure the normal operation of the plate heat exchanger and prolong the service life of key components, it is especially important to understand the failures of the plate heat exchanger, their causes, and treatment methods. The following is a description of how to deal with the heat exchanger when the pressure drop is too large. Here is the content list: Large pressure drop Causes of large pressure drop…

Which Floor do you interested in?

May I have your contact info?