Working Principle

Finned tube heat exchangers is a kind of heat exchange equipment most widely used in gas and liquid. To achieve the purpose of strengthening heat transfer, the fins with horizontal and vertical are added in the surface of base tube. Although there are many forms of physical structure, the basic structure is made up of parallel plate and assembled plate bundle consist of various forms of fins.

Specification

| Medium | Air. olio. acqua. wind | |||

| Fins | Fin types | application | features | Width series |

| BW(wavy-fin) | external fin | Widely used(better heat emission capacity) | 2.0mm,2.5mm, | |

| 3.0mm,3.8mm | ||||

| 4.7mm,5.6mm, | ||||

| JC(serrated-fin) | Internal&external fin | Widely used(better heat emission capacity);large friction resistance | 6.5mm,8.0mm, | |

| DK(perforated-fin) | Internal fin | 9.0mm,9.5mm, | ||

| PZ(plain-fin) | Internal&external fin | Used in construction machinery | 10.3mm,11.3mm | |

| BY(Louvered-fin) | External fin | 11.7mm,12mm | ||

Veriety of heat exchangers

| Classification according to The medium | 1)Oil cooer; water radiater; air cooler; intercooler; | |||

| 2)Combined oil-water cooer; combined oil-air cooer; combined water-air cooler; combined oil-air-water cooler | ||||

| 3)air separator; condensator evaporator | ||||

| Classification according to the application | For engineer machinery(excavator,loader,bulldozer,rullo,drilling,crane,paver,scraper and so on) | |||

| For compressor(screw compressor and reciprocating compressor) | ||||

| For chemistry industry | ||||

| For petroleum chemical industry | ||||

| For automobile | ||||

| For watercraft,marine engineering | ||||

| For offshore engineering | ||||

| For steel industry | ||||

| For HVAC | ||||

| For textile industry | ||||

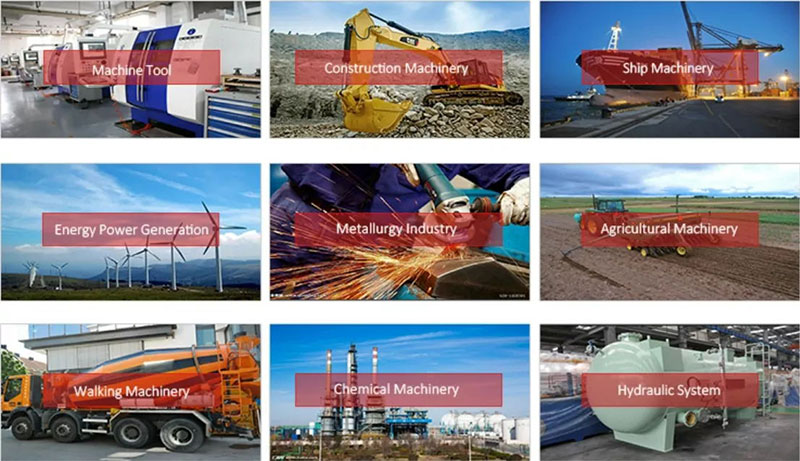

Application: