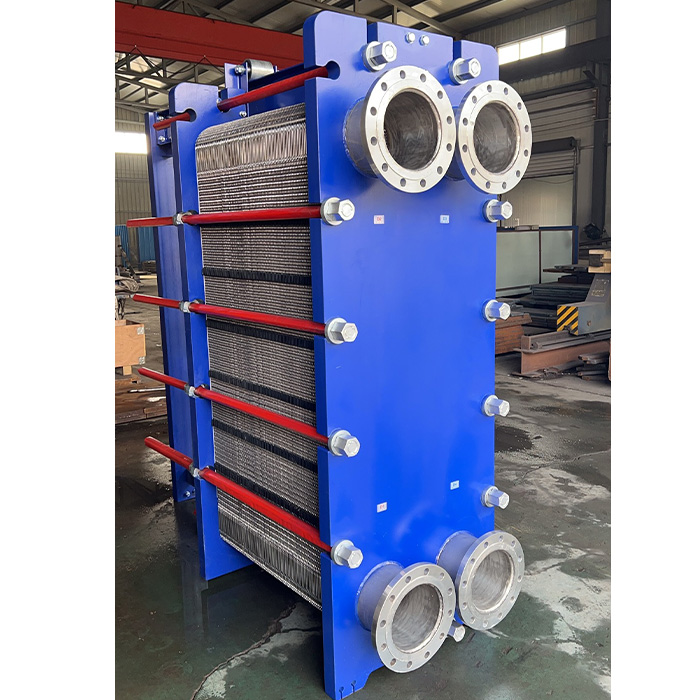

Semi-welded plate heat exchanger are specially provided for heating and cooling of corrosive media. They are widely used in ammonia refrigeration, sulfuric acid, caustic soda, petrochemical, 冶金, 机械, pharmaceuticals, food and other industries, especially suitable for ammonia and Freon. Such as the evaporation and condensation of refrigerants, it is also an ideal heat exchange equipment for the medium that corrodes gaskets in chemical and general process heat exchanges.

1. Working principle

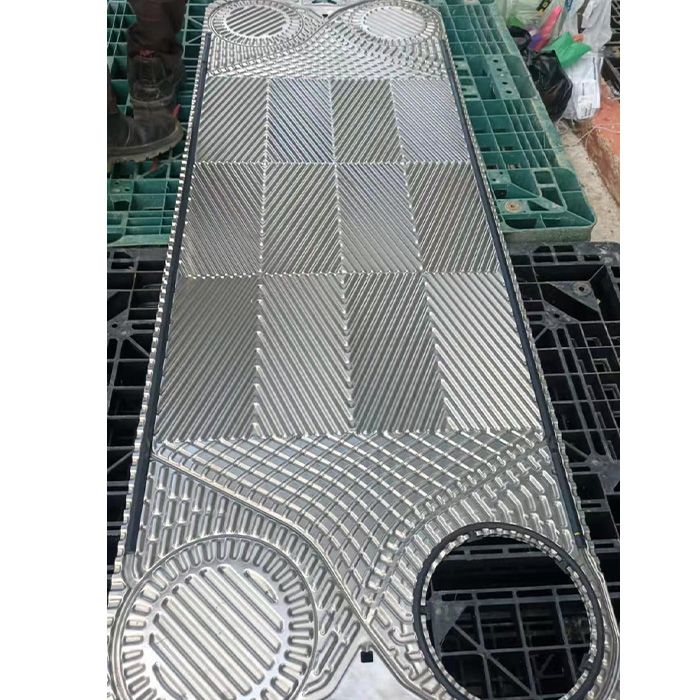

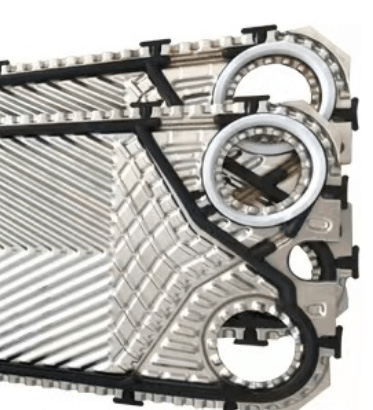

The structure of a semi-welded plate heat exchanger is that each two corrugated plates are positioned back to back and laser welded together as a “box” along the sealing groove designed for the gasket of the semi-welded PHE. That is, every two corrugated plates are welded together, and then they are assembled together and sealed with gaskets. PHE’s semi-welded plates are specially used for corrosive media. This structure has a welding seal on one side and a gasket seal on the other side, eliminating the risk of corrosion of the sealing strip. Sensitive media flows through the welded flow channel, and conventional media flows through the conventional flow channel for heat exchange.

2. Advantages

1. Laser welding – safe and efficient

Using mature laser welding technology and then sealing it with a gasket, it has high heat transfer efficiency, long service life, is not easy to leak, is easy to repair, and has a high safety factor.

2. The plate material is resistant to high temperature and high pressure

The plates of the semi-welded plate heat exchanger are made of 304/316L/titanium plate/Hastelloy high-strength and corrosion-resistant material, which is not afraid of high-corrosion and high-temperature media and has a high pressure of 5.0MPA.

3. Adhesive-free rubber gasket design for long-lasting sealing and high corrosion resistance

Since neoprene sealing gaskets have high corrosion resistance, laser semi-welded plate heat exchangers use this material as the gasket raw material. The bonding-free system installs the gasket in a specially designed groove to make the gasket and the media The contact area is minimized and its service life is extended. The gasket also has the advantages of easy cleaning and good resistance to thermal stress.

4. Unique flow channel design to enhance heat transfer

The flow channel design can increase the turbulence intensity when the medium flows into the plate heat exchanger, enhance the heat transfer effect and reduce the corresponding pressure loss. Even if the flow rate of the medium in the heat exchanger is very low, a high heat exchange effect can be obtained. In order to meet the requirements of different working conditions, we have different plate types to choose from.

5. Adjustable size and easy to disassemble and assemble

It is easy to disassemble and assemble. The plates enclosed by the sealing gasket can be disassembled for cleaning or cleaning or plate group replacement. Easy to install and simple to maintain. It can be cleaned and repaired, has a long service life and low operating costs. Strong plasticity and flexible adjustment. The amount of heat transfer can be adjusted by adding or subtracting plate groups.

3. Application industries

1. Refrigeration, air conditioning and HVAC industry: can be used as evaporator gas superheater, liquid subcooler, heat recovery device, ETC。;

2. Chemical industry: 加热, 冷却, evaporation, and condensation processes;

3. Metallurgical industry: lubricating oil cooling and circulating water cooling of rolling mills and continuous caster refrigeration machines;

4. Electric power industry: transformer oil, turbine oil cooling;

5. Light textile and papermaking industry: waste heat utilization of waste gas and waste liquid;

6. Regional centralized heating: steam-water heating, intermediate heat exchange station, secondary system water heating;

7. Pharmaceutical industry: water for injection, plasma manufacturing.

Semi-welded plate heat exchangers are widely used in food, 药品, municipal water supply, 冶金, electric power and chemical industries.